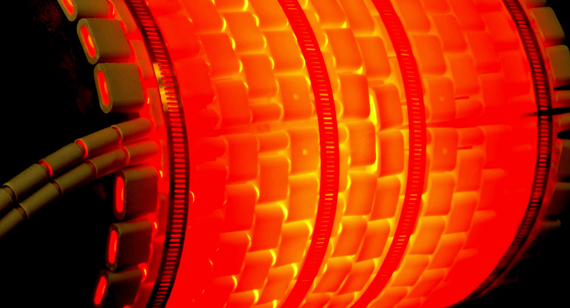

Stress Relieving is a heat treatment process used to reduce residual stresses in metal parts that result from welding, machining, or cold working. The material is heated to a specific temperature below the transformation range and then cooled slowly in still air. This controlled heating and cooling cycle helps improve dimensional stability, reduce distortion during further processing, and increase fatigue resistance in critical components. It is commonly applied to large fabricated structures and precision-machined parts.